Design House For Innovative Photonics

Control your Photonic Components supply chain with bright solutions

Serving Leading Automotive customer

Serving Leading High-Power laser customer

Serving leading Datacom and Medical customers

As a key partner in your quest for a customized solution, and to control your supply chain, our team of experts can optimize your most challenging needs across four comprehensive phases.

Customer: Leading global customer

Goals and motivation: Improved production yield and signal SNR

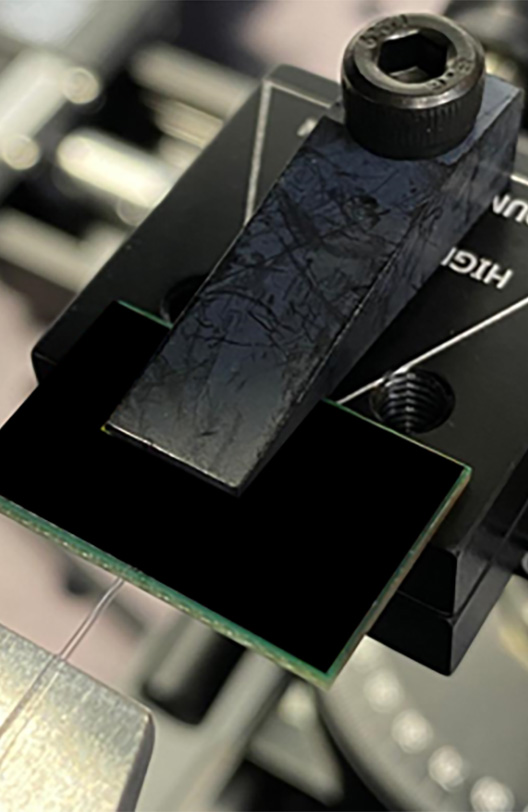

Project highlight: Multiple fiber fusion splicing to waveguides in photonic chips. IP-based solution. Fusion splicing of fibers is stronger than adhesives, more robust and provides lower optical losses

Customer: Picodya

Goals and motivation: Gen 2 full optic system for Improved blood exam processing, miniaturization and product COGS reduction

Project highlight: Novel IP based solution – Miniaturized optical assembly, including customized multiple waveguides that allow illumination of the sample and light collection based on Picodya B-matrix® innovative concept for point-of-care tests

Customer: Leading high power laser manufacturer

Goals and motivation: Providing the customer with better control over their supply chain for securing second source and for custom-made modifications

Project highlight: New active customized high power laser fiber for production tools/machines. Targeting mass production and 2nd source of the supply chain

Activity:

Couple hours of free discussion with our most relevant ad-hoc team of experts; understanding the problem statement, your essential needs and targeted KPIs.

Deliverables:

Through this session, together we will build a common ground base and freely brainstorm ideas for solutions. Such sessions will also give you a first-hand impression of our relevant experts and teams that may be assigned to your targeted project. Based on that session, the customer may choose/narrow down the lead/leading suggested solutions on which to focus.

Activity:

A collaborative effort for details requirements specification document and define and quantify measurable targeted KPIs.

Deliverables:

Qualified requirements specification and focused measurable key targets documents.

Activity:

Together, we will choose and analyze the optimized solution and build a full program plan, including project milestones, project budget, risk mapping, and timeline phases.

Deliverables:

Preliminary solution plan with a related program plan at least for phase 1.

Activity:

Simulate, design and build the proof of concept; demonstrate it and run it through test performance and gap analysis.

Deliverables:

Proof of concept test analysis.

Activity:

Collaborative effort update for targeted prototype.

Deliverables:

Optimization of the program plan.

Activity:

Build the first full prototype, demonstrate it and run it through verification and validation performance testing based on the set KPIs in the program plan.

Deliverables:

Prototype performance test analysis report.

Activity:

Collaborative effort update for first product and DFM phase.

Deliverables:

Tuned program plan for next phase.

Activity:

Demonstrating the first product, including DFM and running it through full performance testing based on the set KPIs on the program plan.

Deliverables:

Performance test analysis report and tuned program plan for comprehensive production process.

Activity:

Build the production process procedures and documents, then run trial manufacturing. Achieve target KPIs in performance, cost, yield, etc.

Deliverables:

Production by order or production process documentation.